Non-destructive testing laboratory services

Non-destructive testing laboratory of IE “Ynamly yol hyzmaty” was founded in 2022 and it is located at the territory of “Balkan” shipbuilding and ship repair plant in Turkmenbashi city, Turkmenistan. NDT with IE “Ynamly yol hyzmaty” - is to inspect a component in a safe, reliable, and cost effective manner without causing damage to the equipment or shutting down the work of production. There are various types of NDT methods, performed by our company, such as visual testing (VT), ultrasonic flaw detection (UT), ultrasonic thickness measurement (UT), radiography testing (RT), magnetic particle detection (MT) and penetrant testing (PT). In addition, the specialists are trained and certified according to IRATA, the leading Association in industrial rope access.

Visual Testing (VT)

Visual Testing (VT) is based on the inspection for flaws that are visible to the naked eye and is the most commonly used NDT method across all industries. It allows for a feasible and fast control of quality at every step of the fabrication or maintenance process.

Penetrant testing (PT)

Liquid or dye penetrant testing (PT) is a non-destructive material testing method which uses capillary forces to find surface cracks or pores and make them visible. It can detect surface- breaking flaws such as cracks, laps, porosity.

Magnetic particle detection (MT)

It is a non-destructive testing process in which a magnetic field is used to detect surface and shallow subsurface in homogeneities in ferromagnetic materials. Examples of ferromagnetic materials include iron, nickel, cobalt and some of their alloys.

Ultrasonic thickness measurement (UT)

It is the main method used to assess the actual value of the wall thickness of structural elements by single measurements in places inaccessible to measuring the thickness of a mechanical measuring instrument.

Ultrasonic Flaw Detection (UT)

Ultrasonic Testing or Ultrasonic Flaw Detection is a type of non-destructive Testing that employs high-frequency ultrasound waves to perform inspections and measurements. Ultrasonic inspection is often used to discover and evaluate flaws, measure dimensions, characterize materials, and more.

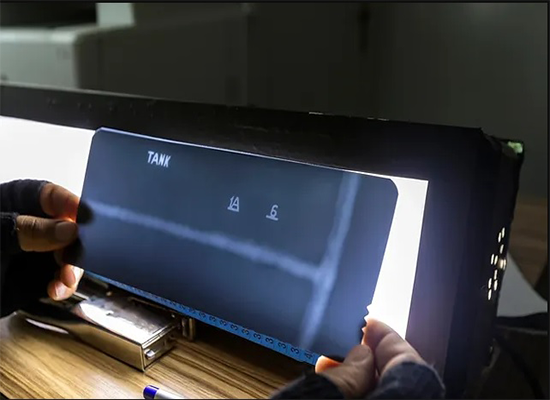

Radiographic Testing (RT)

Radiographic Testing (RT) is a non- destructive testing (NDT) method, which uses either x-rays or gamma rays to examine the internal structure of manufactured components identifying any flaws or defects. In Radiography Testing, the test-part is placed between the radiation source and film (or detector).